About Syndiant

Hand-held consumer electronics are constrained by their small screen size. Ultra-portable projectors, or pico projectors, allow consumers to enjoy a large screen experience in portable electronics, such as smart phones, notebook computers, digital media players, game consoles and cameras. OEM Customers indicate that all key technology elements are ready with the exception of a light modulator that meets cost, form-factor, resolution and power requirements.

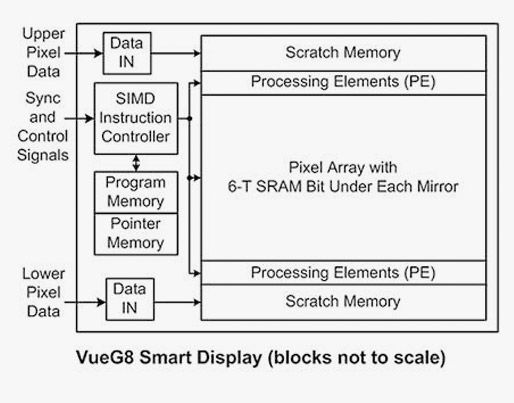

Syndiant’s technical advantage lies in its patented architecture, which uses powerful but elegantly simple parallel processing to enable the world’s smallest and highest resolution light modulating chips used in ultra-portable or pico projectors.

Management Team

Chairman

Felix Y. Chen serves as Chairman of the Board of Directors. Mr. Chen also currently serves as a director on the executive board of the SMU Cox School of Business and as a member of the board of John Goodwin Tower Center at Southern Methodist University. He is the past president of the National Chinese American Jewelry Association.

Mr. Chen was born in Shanghai and moved to Taiwan. He came to the U.S. in 1970 to complete his Master Degree in pure mathematics at the University of Miami in Florida. A man of many interests, he started a jewelry business in 1978. Mr. Chen currently serves as chairman and CEO of PAJ, Inc., the leading jewelry manufacturer and wholesaler servicing all major department stores and mass merchants in the U.S. and Canada. He is also a partner of Prime Real Estate Management, Inc., a real estate holding company

Daniel Wong, Ph.D.President and Chief Executive Officer

Dr. Wong brings to Syndiant more than 30 years of well-rounded business management experience in the semiconductor industry. Since 2010, Dr. Wong has been the Executive Director and General Manager of Gerad Technologies (Suzhou), a semiconductor assembly and test foundry. Prior to joining Gerad Technologies, Dr. Wong served as the Regional President of Asia Pacific of Qimonda from 2006 to 2010. He has experience managing a business with a revenue exceeding 1.5 billion (USD $1.85 billion), a work force of more than 4,000, spanning sales and marketing, product development, manufacturing, strategy planning and public relations.

Dr. Wong co-founded Ardent Technologies in 1998, where he served as President and CEO before Infineon acquired the company in 2000. From 2000 to 2006, Dr. Wong held several executive positions at Infineon: Vice President and General Manager of LAN Business Unit, the Vice President and General Manager of Broadband CPE Business Unit and the Managing Director of Infineon Taiwan. He spearheaded business and product development for Ethernet LAN switches, IP-Phone, and Broadband CPE.

In 1990, Dr. Wong co-founded Pericom. In 1993, he transformed I-Cube into a fabless company delivering networking solutions. He served as Vice President of Operations and Engineering at both companies. Previously, Dr. Wong spent eight years at IDT and IBM, and is a named inventor on 14 U.S. issued patents. Dr. Wong earned his Ph.D. and MS in Materials Science and Engineering at Stanford University in California, MS in Physics at Rutgers University in New Jersey and his BS in Physics at National Tsinghua University in Taiwan.

Timothy RostGeneral Manager, Syndiant Inc.

Vice President, Research and Development

Timothy Rost brings over 16 years of startup experience in semiconductors and consumer electronics. Heading the U.S. operations and responsible for research and development of microdisplay products, he has led software engineering at Syndiant since 2006. Mr. Rost is also an expert on colorimetry and display calibration, and previously handled all IC physical verification for TestChip Technologies. Rost earned his MS in Informatics at the University of Edinburgh in Scotland, and BS in Electrical Engineering and BA in Economics from The University of Texas at Austin.

Frank HuangGeneral Manager, Syndiant Taiwan

Vice President, Finance and Administration

As the GM of Syndiant Taiwan Branch and head of Finance & Controller of Syndiant, Frank Huang brings more than 25 years of experience in finance management to the company. Formerly a CFO at CMMB Vision Holding Ltd. for eight years, he had complete responsibility for finance and business operations. Frank Huang has finance operation experience in electronic, telecom and banking industries. Frank Huang earned his Bachelor of Industrial Administration degree at National Taiwan University of Technology, and his MBA degree at the University of Houston.

Michael LyuVice President, Operations

Mr. Lyu has over 30 years of experiences in Hi-Tech arena, especially in IC manufacturing. He holds a full spectrum of knowledge in IC manufacturing technology and specializes in product identification, development, yield improvement , operations and sales. Throughout his career, Mr. Lyu has worked for prominent international companies such as “Intel” and “LSI Logic”; he also founded a company himself. Mr. Lyu has been in multiple leadership roles in the companies with different business disciplines, and constantly exhibits the capability of achieving any tasks presented before him, especially in IC process integration, operations and organization management. Mr. Lyu earned his MS in Materials Science and Engineering at Stanford University and BS in Physics from National Tsinghua University in Taiwan.

Eric PengGeneral Manager, ZJK Syndiant

Vice President, China Business Development

Eric Peng has more than 20 years of experiences in project management, business consultant, business development, and investment. Eric started his career with Nortel (China) in 1993, gaining tremendous experiences in project management and dealing with China SOE as Regional Project Chief. Eric joined Fedex (Canada) in 2005 as System Maintenance Engineering Project Coordinator. In 2007, Eric joined Beijing HolyYard Environmental Protection Devices Co. Ltd. as its Vice General Manager. Prior to joining Syndiant, Eric was the Vice President of Beijing DeMei Investment Co. Ltd. responsible for its investments and M&A activities.

Eric Peng earned his Master Diploma of Private Equity and IPO in Finance and Investment Program at HSBC Business School of Peking University, China; MS in Telecommunication Engineering at School of Engineering Science of Simon Fraser University, Canada; BS in Semiconductor and Microelectronics at School of Electrical Engineering of Tsinghua University, China.

Sean ShiGeneral Manager, Syndiant (Suzhou) limited

Vice President, China Sales

Sean Shi brings nearly 30 years of experience in both state-owned and foreign invested enterprises, successively engaged in R&D, project management, sales & marketing, and corporate management. He joined Syndiant in 2016 and currently serves as VP of China sales and GM of Syndiant (Suzhou) limited. Mr. Shi has more than ten years of semiconductor industry experience with senior management, sales, and operations roles at Qimonda, Gerad, and WLCSP. He earned a BS in Optical Instruments at Tianjin University and pursued an MBA at Soochow University.

Hiap Ong, Ph. D.Vice President, Process and Optics Development

Dr. Ong brings to Syndiant more than 30 years of technology and product R&D experience in microdisplays and direct-view LCDs. Dr. Ong invented the wide-viewing angle TN/LCD using compensation films, MVA using protrusion geometry, and simple MVA with no protrusions and no ITO slits. These three technologies are widely used in LCD industry. He has also made significant contributions to microdisplays, LCD optical modeling and characterization, and color sequential LCD technology. His previous employment includes 16 years at Taiwan Kyoritsu Optronics as President, 16 years at Kopin Corp as Chief LCD Technologist and VP Asia Division, 10 years at IBM as Research Staff Member, and Assistant VP at Taiwan E Ink Holdings Inc. and Quanta Display Inc. He is a named inventor on 77 issued patents, published 98 papers, delivered 47 invited talks and co-edited a book on LCD technology. He served as Taiwan ITRI LCD Technical Advisory Council member, SID Mid-Atlantic Chapter Chair, SID Seminar Chair and Award Chair, USDC Technical Council Member and LC Project Chair. Dr. Ong received 4 IBM Awards, the Glenn Brown Award for Outstanding Liquid Crystals Ph.D. Thesis, the SID Special Recognition and Fellow Awards, and the Taiwan Ministry of Economy Affairs Industrial Advanced Technology Innovator Award. Dr. Ong earned his BSc in physics and mathematics at Nanyang University in Singapore and his Ph.D. in physics at Brandeis University.

Dennis Cheng, Ph. D.Senior Manager

Technical Marketing and Sales

With more than 10 years of technology development experience in LCOS micro-display, Dr. Cheng is responsible for managing Syndiant HK Ltd., which functions include LCOS electronics solutions development, customer technical support and new projects development with the local R&D organizations in Hong Kong. Cheng earned his BEng, MPhil and PhD degrees in Electrical and Electronics Engineering at the Hong Kong University of Science and Technology, and MBA degree at the University of Bradford, UK. He is an expert in the field of LCOS micro-display and its related technology such as LCD, projection optics and LCOS electronics for multi-media application. He also has solid business development experience in the LCOS micro-display industry.